We

are pleased to announce that the PVC range of instruments will be under the

management of Thyracont Vacuum Instruments GmbH (www.thyracont.de) from January 2021.

For all enquiries, please contact: direct@thyracont-vacuum.com

EpiMax would like to take the opportunity of thanking all our loyal customers for their help and support over many years; we feel confident that the PVC range has a bright future with Thyracont.

A key function of the PVC is to act as an "Interlock Hub" to provide protection to the gauge and your system. The Interlock Hub is completely user-configurable, often removing the need for external sensor/switch units and reducing the amount of hard wiring required.

The Interlock Hub links together the ion gauge performance, the secondary gauge measurements, digital output trips, digital inputs, analogue outputs and bake-out in a simple to define user-configurable matrix:

Parameter | PVCuni and PVCduo |

| ION GAUGE: | |

Ion Gauge: | PVCuni: 1x Dual filament UHV. Thoria- or Yttria-coated Iridium filaments PVCduo: 2x Dual filament UHV. Thoria- or Yttria-coated Iridium filaments (simultaneous operation of both gauges) |

Filament Drive: Emission Control: | Constant current dc (4A/9V) µprocessor controlled precision PID control |

Manual Emission: | User selections: 0.06, 0.1, 0.15, 0.25, 0.4, 0.6, 1, 1.5, 2.5, 4, 6, 10mA |

Auto-emission: | Emission automatically adjusts for optimum performance at the measured pressure |

Emission features: | Soft-start. Optional "new filament" setting to permit gentle heating. User-definable min & max emission |

Degas: | Ramped low/mid/high power |

Degas Features: | User-defined ramp/soak periods. User-defined pressure suspend to allow vacuum recovery. |

Degas Pressure: | Continuous measurement during degas |

Degas on/off: | No interruption to pressure measurement during degas start/stop |

Electrometer: | Effective Range: 0.1pA to 1mA; equates to 1x10-13 to 1 mBar (gauge dependent) High thermal stability, low drift |

Sensitivity: | 1.0 to 99.9 (resolution 0.1) |

Pump-down: | User-defined auto pump-down: backing gauge dependent ion gauge start-up pressure; trip allocation for external events (valves...), delay time, restart time etc... |

| SECONDARY & TERTIARY GAUGES: | |

Built in: | Supports VSP521 or VSP841. User calibration available. |

Number of Modules: | 2 |

Tertiary Gauge Module Options: | "V": VG Pirani "E": VSP521 "F": VSP841 "W": Universal for output from other gauge controllers or active gauge heads such as cold-cathode gauges (e.g. PKR251/261, IKR270), mini-convectron, Stinger, microPirani...). Note: some of the gauges can draw their power from this module (max 100mA@14.5V). |

| BAKE-OUT CONTROL: | |

Built in: | Type K thermocouple. Standard mini-thermocouple connector |

Range: | Room temperature to 900°C (16 bit resolution). Precision CJC. Reproducibility <±0.2°C. Absolute <±2°C. User calibration available. |

Bake-out Functions: | 6x ramp/soak steps, each up to 99.9 hours duration. Individual trip allocation for power switching (e.g. 3 trips for 3Φ). User-defined pressure interlocking (ramp suspend/time suspend/abort). User-defined temperature hysteresis. Optional auto-degas at end of bake-out. |

| INTERLOCK HUB: | |

Trips: | 7 (4x SPCO relays 1A24Vdc/ 0.5A125Vac + 3x NPN open collector 100mA/12Vdc) |

Trip assignments: | Individually assignable: external interlock to any ion or backing gauge, ion gauge status (on, off, degas), bake-out power switching, pump down external drive... |

Digital Inputs: | 4x opto-isolated inputs. 3-30Vdc; 2.4kΩ input resistance. |

Digital Input assignment: | External interlock as trip for ion gauge; control over ion gauge on/off and degas either via input state or toggle state, bake-out trip, pump-down trip, backing gauge operation... |

Interlock Response times: | 0.2 sec max. Typically <0.1sec |

| ANALOGUE OUTPUTS: | |

2x Outputs: | Full scale range: 0V to 10.2V (12 bit resolution). User-definable min and max voltage and related pressure value |

Accuracy: | Precision reference-based: <±0.2%. |

Assignment: | Ion gauge (emission and sensitivity corrected), any secondary gauge, gauge combinations, bake-out temperature... |

Functionality: | User-defined voltage range vs. assigned pressure/temperature range. Linear or logarithmic relationship... |

| GENERAL: | |

Dimensions: | 19" rack mounting: WxHxD: 484x44x260mm |

Weight: | 6kg. |

Electrical: | 115/230Vac. Live and Neutral fused: 2A for 230Vac, 3.15A for 115V |

Power Consumption: | 4W (ion gauge off); max: 40W (high degas); typical: 4-10W (ion gauge on). |

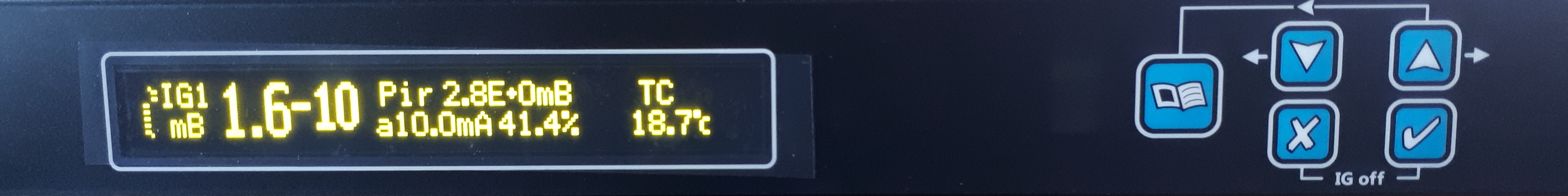

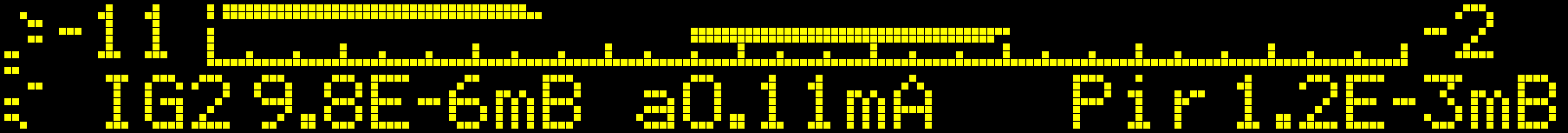

Display: | Single gold OLED display. Graphical 200x16 pixel resolution |

Data Resolution: | Ion gauge: Pressure: 1 or 2 decimal place resolution; Current: 4 significant digits (mA/µA/nA/pA) Secondary/Tertiary gauges: 1 decimal place resolution. Temperature: <0.05°C measurement resolution, 0.1°C display resolution. |

Manual input: | Intuitive menu-driven via 5 front panel touch buttons |

Comms ports: | Multi-drop RS232 (up to 8 units (port dependent)) and RS485-3 wire (up to 16 units). [Mid-2014: TCP/IP option] |

Comms Settings: | 4800, 9600, 19200, 38400, 57600 baud. Parity: None, Odd or Even. 8 bit + 1 start + 1 stop |

Comms Protocols: | MODBUS RTU protocol. Multiple parameter read/write; floating point resolution. QueBUS protocol: ASCII-based with multi-parameter read/write messaging. |

Comms connection: | 2x RJ45 for simple daisy-chaining |

Dimensions of all PVC models. Please add 50mm for rear panel earth stud and connectors